ZINDN Specification

Packages by tin

25kgs (9.25liter)/tin

10kgs (3.7liter)/tin

5kgs (1.85litre)/tin

2kgs (0.74liter)/tin

Aerosol spray (420ml)

ZINDN Spray ZD96-21

ZINDN ALU Spray ZD90-21

ALU Spray ZD18-16

ZINDN Dual Protection Mechanism

ZINDN is one of the few existing anti-corrosion technologies that can achieve a combination of cathodic protection and barrier protection.

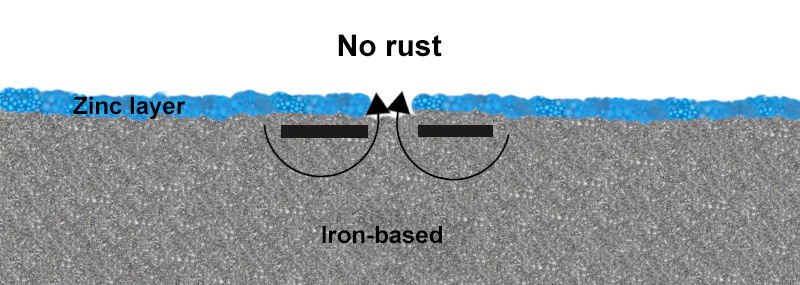

Cathodic Protection

The sacrificial anode is one of the important means of cathodic protection. The sacrificial anode method is used to achieve cathodic protection of steel. Zinc is a commonly used anode material in the sacrificial anode method. The standard electrode potential of zinc is -0.76V, which is more active than iron's -0.44V. When zinc is coated on steel substrate, zinc will be preferentially corroded and released electrons to flow to the steel, thereby protecting the steel substrate from corrosion. ZINDN uses ultra-pure ultra-fine zinc dust with special conductive fusion agent, which has more excellent cathodic protection performance.

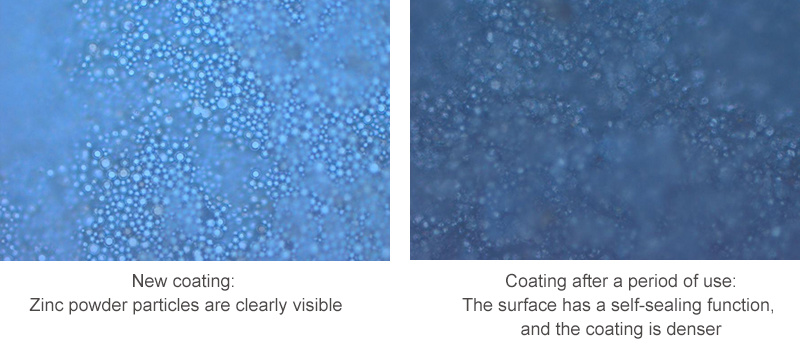

Barrier Protection

The zinc layer exposed to the environment will gradually react with water and air in the environment over time to form stable basic zinc carbonate (commonly known as white rust). The corrosion product is filled between the zinc powder gaps, making ZINDN layer denser, and further blocks and shields the corrosion of corrosive media. ZINDN layer has a self-sealing function.

ZINDN Experimental Performance Comparison

Experimental performance comparison

Experimental performance comparison

| Items | Hot-dip | Arc spraying zinc (aluminum) | ZINDN |

| Surface Treatment | Pickling and rinsing | Sa3 level | Sa2.5 level |

| Application Method | Hot dip | Arc spraying zinc; Oxygen; B block hot spraying zinc (aluminum) | Brush, roller, air spray, airless spray, dipping |

| Application Difficulty | Difficult | Difficult |

Easy |

| Onsite Application | Can't | Difficult with conditions |

Convenient and flexible |

| Energy Consumption | high | High |

Low |

| Efficiency | Depending on the scale of hot plating plant | 10m²/h by arc spray zinc; 50m²/h by arc spraying aluminum |

200-400 m²/h by airless spray gun |

| Environment and Safety | The plating solution produce a large amount of toxic substances, waste liquid and gas | Produce serious zinc fog, dust, cause occupational disease | Free of lead, cadmium, benzene, etc. Application is the same as painting, and serious pollution is avoided. |

| Touch up & Recoating | Can’t | Maintenance is difficult and can’t be recoated |

Easy |

On-site Application Effect

ZINDN Protective Systems

Single layer system

Excellent protective performance

Cost-effective

Recommended film thickness: 80μm-120μm

Duplex system

ZINDN (80μm-100μm) +Silver metallic sealer (20μm-30μm)

ZINDN (80μm-100μm) +Silver zinc rich (30μm-40μm)

ZINDN(ZD96-4) (60μm-80μm) +Powder coating (60μm-80μm)

Triplex system

ZINDN (60μm-80μm) +ZD Sealer (80μm-100μm) +Polyurethane/Fluorocarbon/Polysiloxane topcoat ((60μm-80μm)

Online Message

Online Message

We will contact you within one working day. Please pay attention to your email.

Contact Us

Headquarters Tel:

Business Hotline:

E-mail:

WhatsApp/Wechat:

Address:

9/F, Wai Chuang Building, 999 Gaolang East Road, Binhu District, Wuxi

Public Security Record No. 32021102000961| Su (tin) dangerous chemical word 02802