Zindn Graphene Zinc Heavy-Duty Anti-Corrosion Coating Helps Swedish Atlas Copco Group

Release time:

Dec 05,2024

Under the blue sky beside the vast ocean, the 1,800-ton gantry crane stands tall. Its star-gray appearance not only adds a touch of industrial beauty to the seaside but also directly reflects the excellent performance of Zindn's graphene zinc technology in the C5 corrosion environment.

Under the blue sky beside the vast ocean, the 1,800-ton gantry crane stands tall. Its star-gray appearance not only adds a touch of industrial beauty to the seaside but also directly reflects the excellent performance of Zindn's graphene zinc technology in the C5 corrosion environment. Port machinery faces harsh corrosive environments, mainly due to factors such as high humidity, salt spray, chemical media, and physical wear, and requires the use of high-performance corrosion-resistant coating materials to extend its service life. From completion to commissioning, the gantry crane still maintains its original style. Its stability and reliability are due to the excellent performance of Zindn’s graphene zinc. This not only extends the service life of the equipment but also protects the safe production of the enterprise.

Part 1

Innovative protection mechanism

Zindn was jointly developed by Suzhou Institute of Nano-Electronics, Chinese Academy of Sciences, and China National Chemical Engineering Co., Ltd.

Donghua Engineering Technology Co., Ltd. is affiliated with China National Chemical Engineering Group Co., Ltd. It originated from the Third Design Institute of the former Ministry of Chemical Industry of China, which was established in 1963. As one of the top 100 survey and design companies in China, the company has been awarded the titles of "AAA-level credit enterprise", "national high-tech enterprise" and "national civilized unit" for many years. The company has comprehensive Class A engineering design, Class I general contracting for petrochemical engineering construction, as well as top qualifications in environmental protection engineering, planning, and design, etc.

Technical Characteristics of Zindn Graphene Zinc

1

Excellent anti-corrosion performance

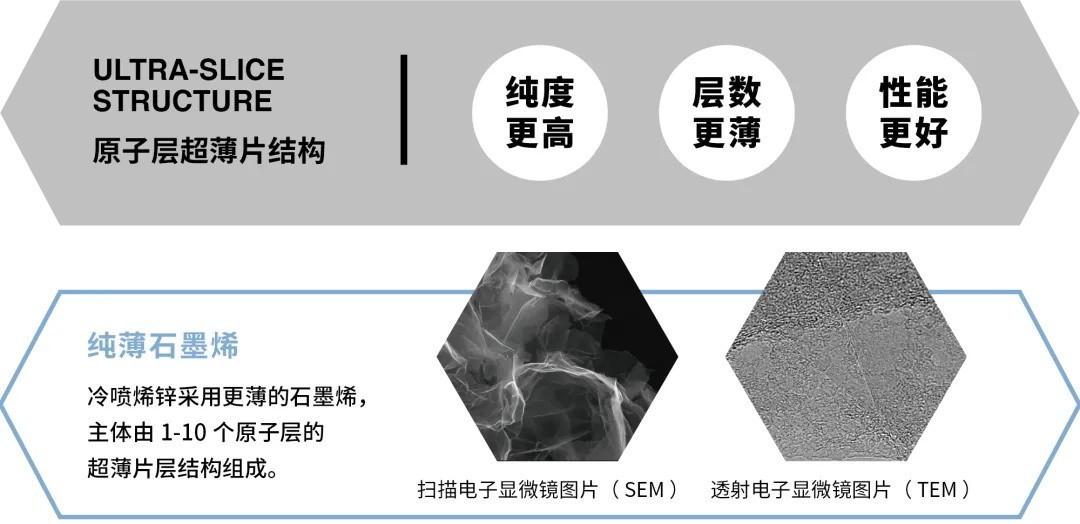

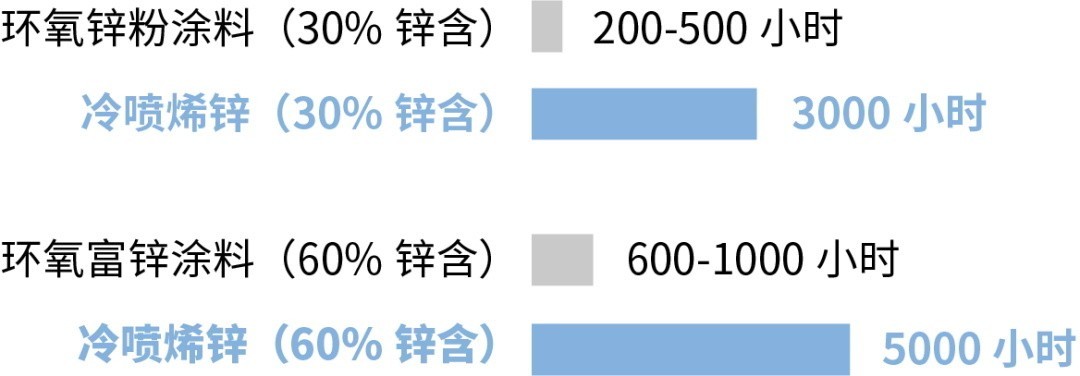

The zinc powder utilization rate exceeds 80%, and it is salt spray resistant for more than 3000 hours. It has physical shielding properties and cathodic protection properties that far exceed those of zinc-rich coatings.

2

High coating rate

The theoretical coating rate of 100μm film thickness reaches 3.1㎡/kg, which saves more than 15% of the dosage compared with epoxy zinc-rich paint.

3

Excellent mechanical properties

The damage range of the weld seam is ≤ 2cm, which greatly reduces the damage rate during transportation and assembly.

4

Excellent mechanical properties

The surface pretreatment requirements are low, the adhesion is 8~25MPa, and the graphene and zinc powder are stably dispersed without agglomeration.

Part 2

Market Comparison Advantages

Reduce lifecycle costs by 58%

Salt spray time is greatly improved!

Compared with other similar products on the market, the advantage of Zindn graphene zinc lies in its innovative formula and the balance of comprehensive performance. By introducing graphene technology, Zindn products not only enhance the anti-corrosion performance but also significantly improve the overall durability and sustainability of the coating, becoming the first choice for many major engineering projects.

Part 3

Zindn Power Star Grey Aesthetics

01.

Zind graphene zinc + epoxy intermediate paint + polyurethane topcoat

Facing the severe challenge of C5 corrosive environment, the graphene zinc solution provided by Zindn has covered this huge gantry crane with a solid protective coat. It is like putting on a super armor, which can effectively resist the invasion of corrosion regardless of high temperature, salt spray, or humid environment.

The star grey color sparkles in the sun, which is not only the charm of color, but also the embodiment of high technology. Every construction is a commitment to the future, and every choice is an insistence on quality.