Cold Shield丨Zindn Cold Galvanizing Anti-Corrosion Technology Builds a Solid Heating Lifeline in Northeast China

Release time:

Apr 23,2025

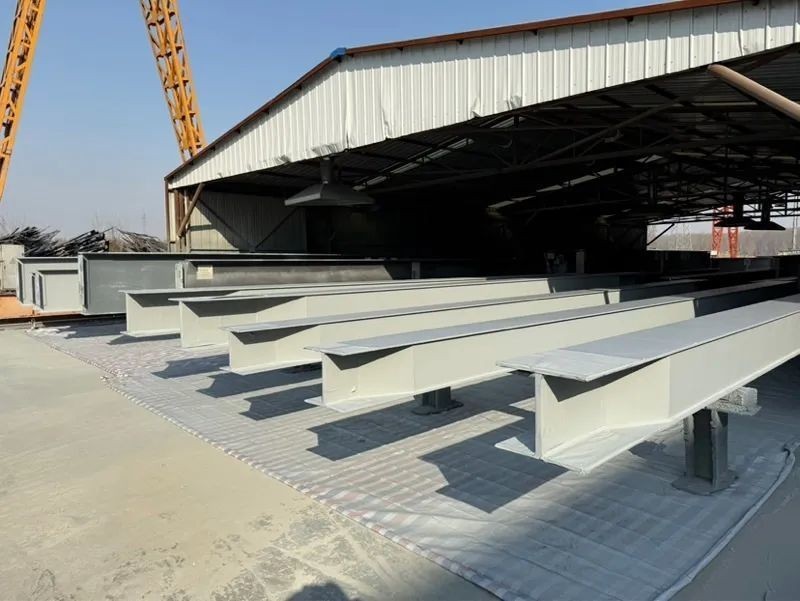

The "huge" project of Guoneng Harbin Thermal Power Co., Ltd. with a total investment of 6.84 billion yuan is of astonishing size: it covers an area of 341,000 square meters, has two 660MW ultra- supercritical units, a heating capacity of 35.35 million square meters, 160 tons/hour of industrial steam, and two DN1400 trunk lines.

1. The first batch of large-scale clean thermal power projects in Northeast China

· Guoneng Harbin Thermal Power Co., Ltd.

The "huge" project of Guoneng Harbin Thermal Power Co., Ltd. with a total investment of 6.84 billion yuan is of astonishing size: it covers an area of 341,000 square meters, has two 660MW ultra- supercritical units, a heating capacity of 35.35 million square meters, 160 tons/hour of industrial steam, and two DN1400 trunk lines. As one of the first "two joint ventures" projects in the country, it also has a green code: the simultaneous construction of environmental protection facilities, such as desulfurization and denitrification, to achieve zero wastewater discharge.

· Guoneng Jilin Thermal Power Plant

The total investment of the State Energy Jilin Thermal Power Plant project is about 3 billion yuan. It is the first thermal power project in Northeast China in the past 10 years. The new unit generates 2.972 billion kWh of electricity annually, provides heat to 12 million square meters, and provides 380 tons of industrial heating per hour. At the same time, the intelligent system ensures safe operation. After it is put into production, the annual output value will be 1.62 billion yuan, which will help optimize the energy structure and significantly reduce coal consumption.

2. Customized anti-corrosion protection for extreme cold weather

· The extremely low temperature in the Northeast region in winter reaches below -30℃, which places strict requirements on thermal power units' cold and corrosion resistance. The two projects use highly weather-resistant anti-corrosion coatings, ultra-low temperature toughness steel, and anti-freeze insulation design to effectively resist extreme cold freeze-thaw erosion and wet cold corrosion, ensuring the stable operation of the units in harsh environments. Anti-corrosion technology greatly extends the life of equipment and reduces maintenance costs; cold-resistant structures ensure zero freezing damage to the heating pipeline network in extreme cold, avoid heat interruptions, protect the safety of heating for people's livelihood, and build a "freezing point defense line" for the Northeast energy system.

· The second phase of Guoneng Harbin Thermal Power Plant adopts a cold galvanizing compound + cold galvanizing compound sealing topcoat anti-corrosion solution, using high-adhesion, fast-curing, environmentally friendly coatings to resist freeze-thaw cycles and salt spray corrosion; Jilin Thermal Power Plant uses "cold galvanizing compound + cold galvanizing compound sealing intermediate paint + polyurethane topcoat" triple protection to enhance the ability to resist ice impact and wet cold erosion. Both solutions achieve zero rust on metal components and zero frost damage on insulation structures in severe cold, ensuring efficient and stable unit operation throughout its 30-year life cycle, and building a solid technical defense line for tens of millions of residents to spend the winter warmly.

3. Zindn Cold Galvanizing Compound

· Cathodic protection

Sacrificial anode is one of the important means of cathodic protection. The sacrificial anode method is used to achieve cathodic protection for steel components. Zinc is a commonly used anode material for the sacrificial anode method. The standard electrode potential of zinc is -0.76V, which is more active than iron's -0.44V. When zinc is coated on a steel substrate, zinc will be preferentially corroded to release electrons to flow to the steel, thereby protecting the steel substrate from corrosion. Zindn Cold Galvanizing Compound uses ultra-pure ultra-fine zinc powder with a special conductive fusion agent, which has better cathodic protection performance.

· Shielding protection

The zinc layer exposed to the environment will gradually react with water, air, and other corrosion products in the environment over time to generate stable basic zinc carbonate (commonly known as white rust). This corrosion product fills the gaps between zinc powders, making the cold galvanizing coating more compact, further blocking and shielding the erosion of corrosive media. The cold galvanizing compound coating has a self-sealing function.

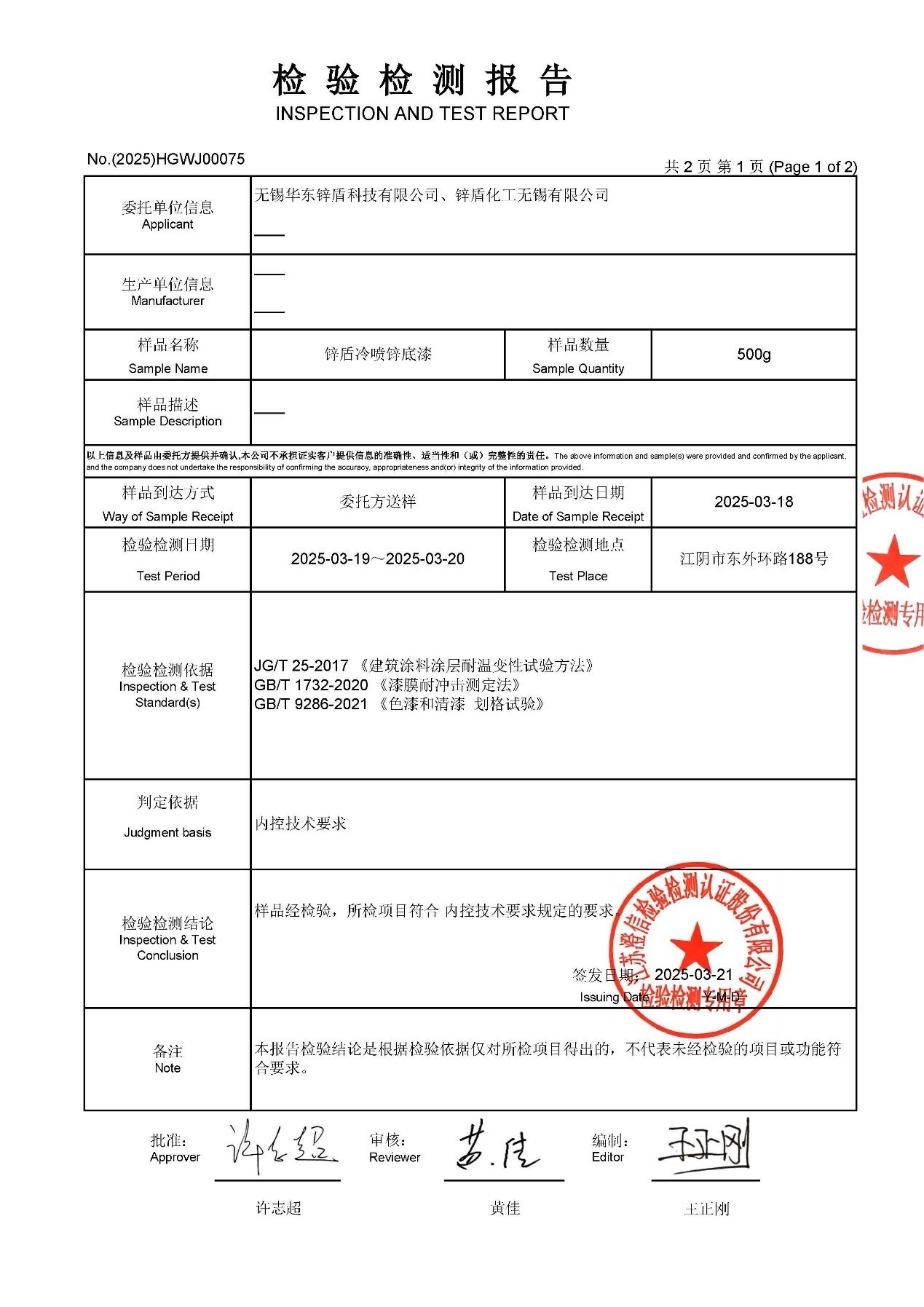

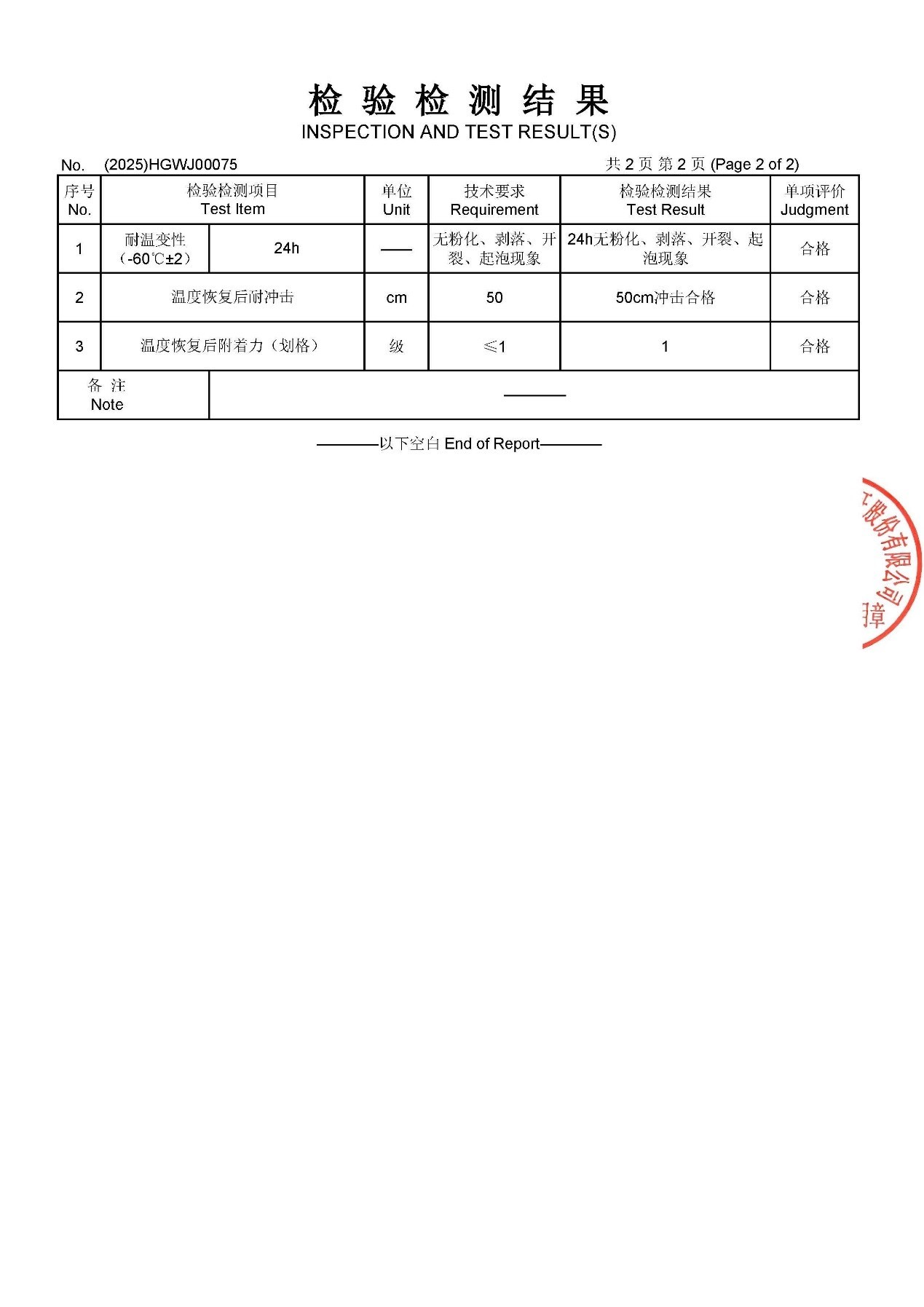

· Temperature resistance test report

Previous